Steel Grating & Stanchion Systems

Premium steel grating solutions for industrial flooring, catwalks, stair treads, and comprehensive handrail systems designed for maximum safety and durability.

ASHMIC Steel Bar Grating

ASHMIC Steel Grating is an open grid assembly of metal bars designed to hold heavy loads with minimal weight. It allows air, light and heat transmission, while providing strength to support everything from light pedestrian traffic to the heaviest vehicular traffic.

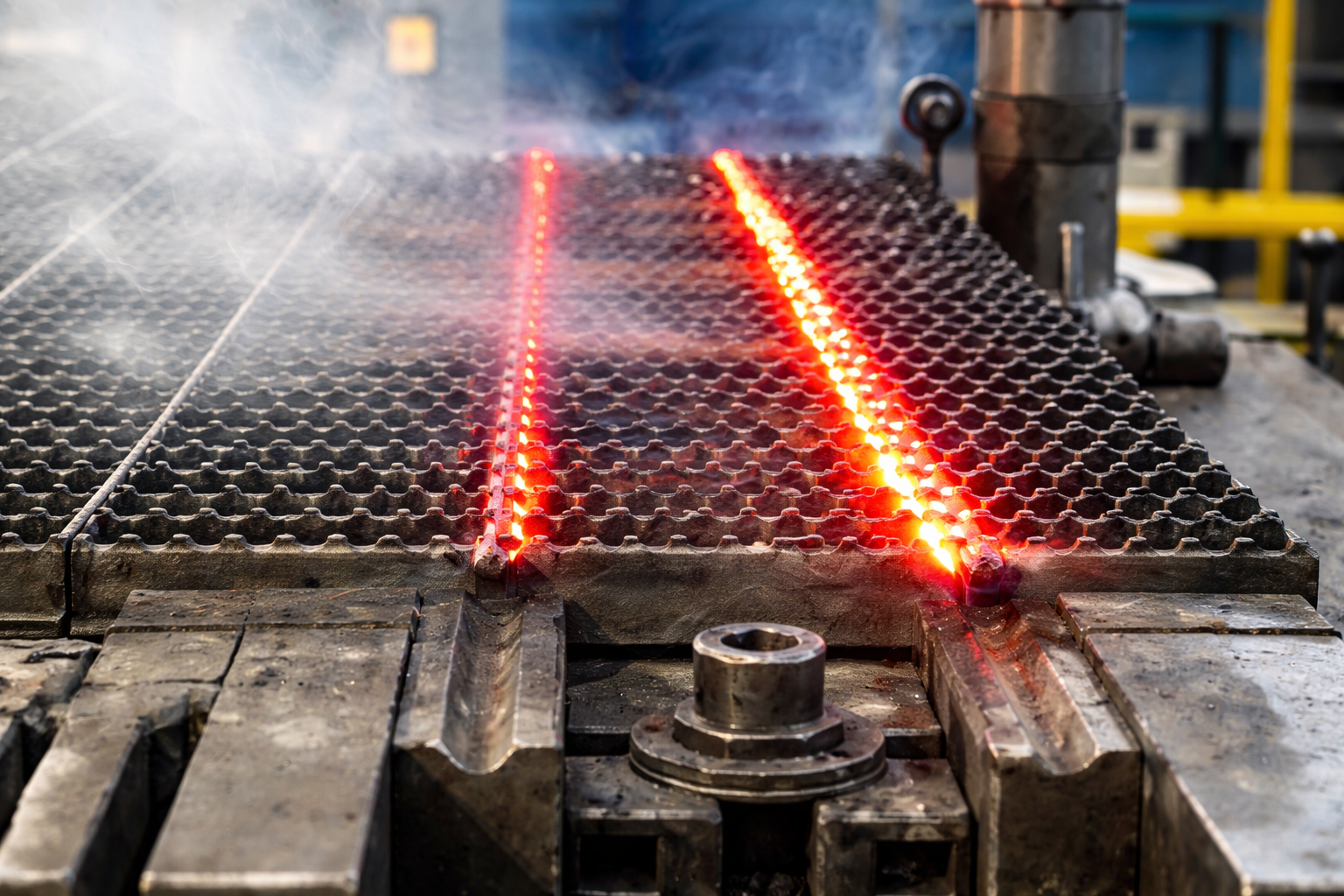

Manufactured through the forged welding process, which has been successfully used worldwide for several decades, ensuring a product of high quality and resistance.

This process consists of welding steel cross bars to perpendicular and equidistant bearing bars through high current and high mechanical pressure discharges, fusing the molecular elements without filler material.

Forged Welding Process

Applications

- Industrial and Commercial Plants

- Mining Underground Vents

- Catwalks and Flooring

- Machine Rooms and Marine Platforms

- Industrial Stair Treads

- Trench and Storm Drains

Advantages

- Allows passage of light and air circulation

- Prevents blockages or accumulation of debris

- Provides lightness and high load resistance

- Increases safety with improved friction

- Durable and long-lasting construction

Product Selection Guide

ASHMIC GRATING is a multipurpose grating system suitable for a variety of industrial applications

ASHMIC GRATING Coding System

Available in numerous combinations of load bar (flat bar) depth and thickness, load bar pitch and cross bar pitch. Part numbers use the following coding system for easy identification:

Brand Identification

ASHMIC Brand ID

Cross Bar Pitch

A = 100mm

B = 50mm

Load Bar Size

Height: 25mm

Thickness: 5mm

Load Bar Pitch

Series 1 = 30mm

Series 2 = 40mm

Series 3 = 60mm

Material

M = Mild Steel

S = Stainless Steel

Load Bar Surface

P = Plain

S = Serrated

Finish Options

Galvanized

Bitumen Dipped

Untreated

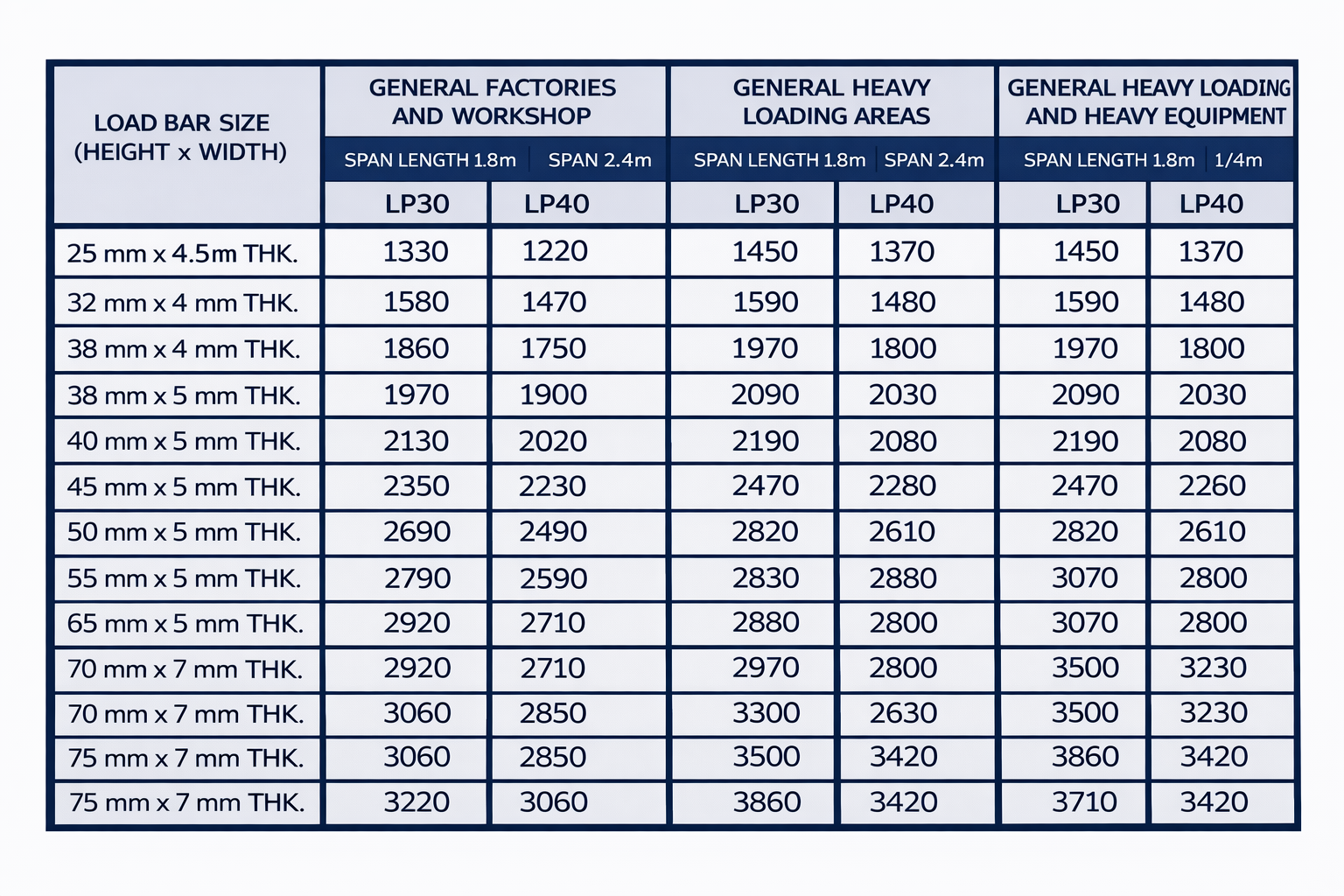

Maximum Recommended Spans

Light and Medium Duty (in mm)

Heavy Duty (in mm)

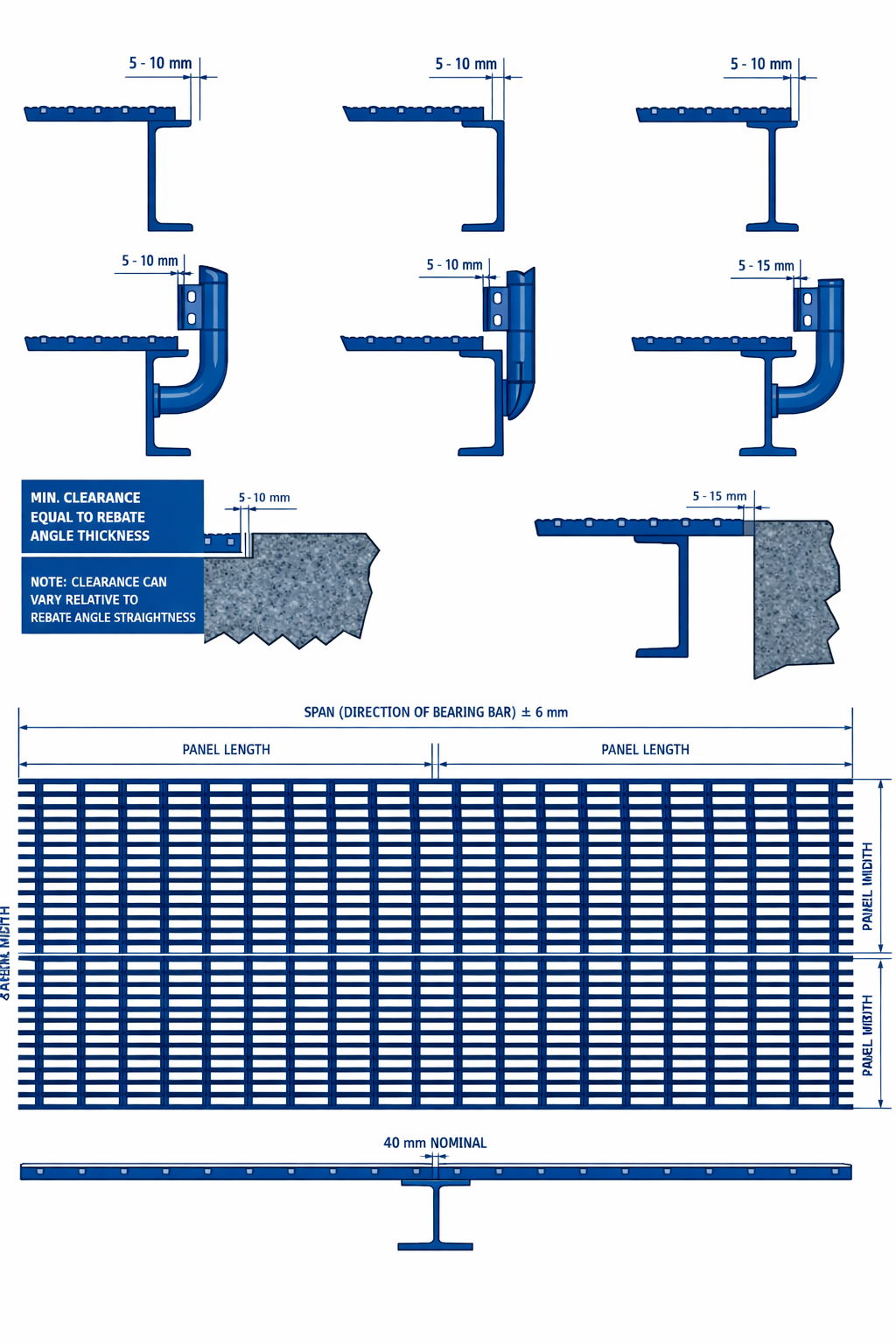

Standard Installation Clearances

Top Treatments & Finishes

Top Treatments

Plain

Standard grating with plain square edge flat bar and 6mm square twisted bar, forged weld on top of load bar.

Serrated

Small notches cut into the load bar during slitting process, providing low-cost solution for improved slip resistance.

Finishes

Untreated

No surface treatment, supplied for custom fabrication

Black Bitumen Dipped

Economical paint finish for indoor installations or dry climate mining applications

Hot Dipped Galvanized

Durable, abrasion resistant coating conforming to ASTM A123/ISO 1461 standards

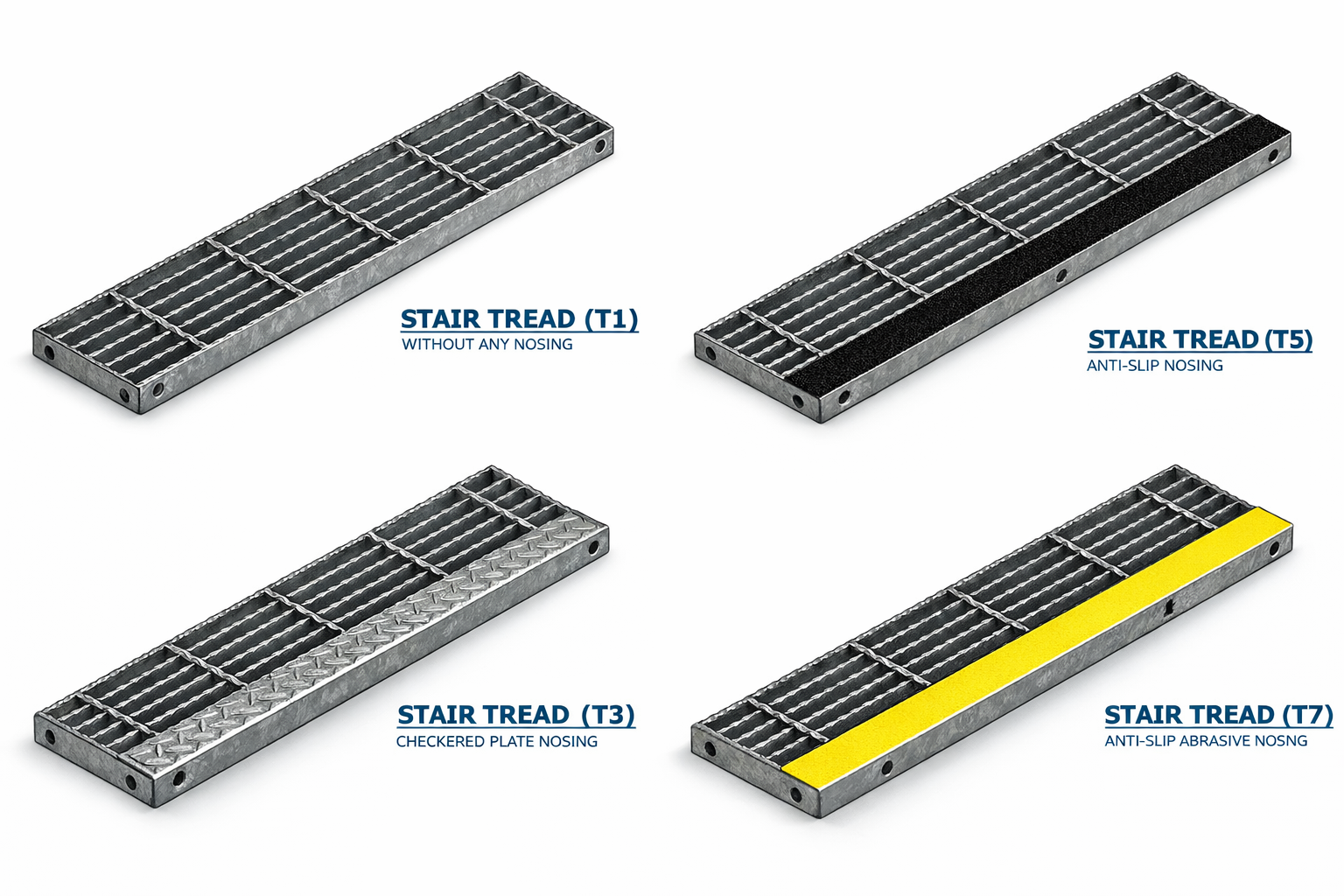

ASHMIC Steel Stair Treads

Available in a variety of grating profiles and tread types

Welded Stair Treads

Bolted Stair Treads

Tread Types & Specifications

Welded Treads

Bolted Treads

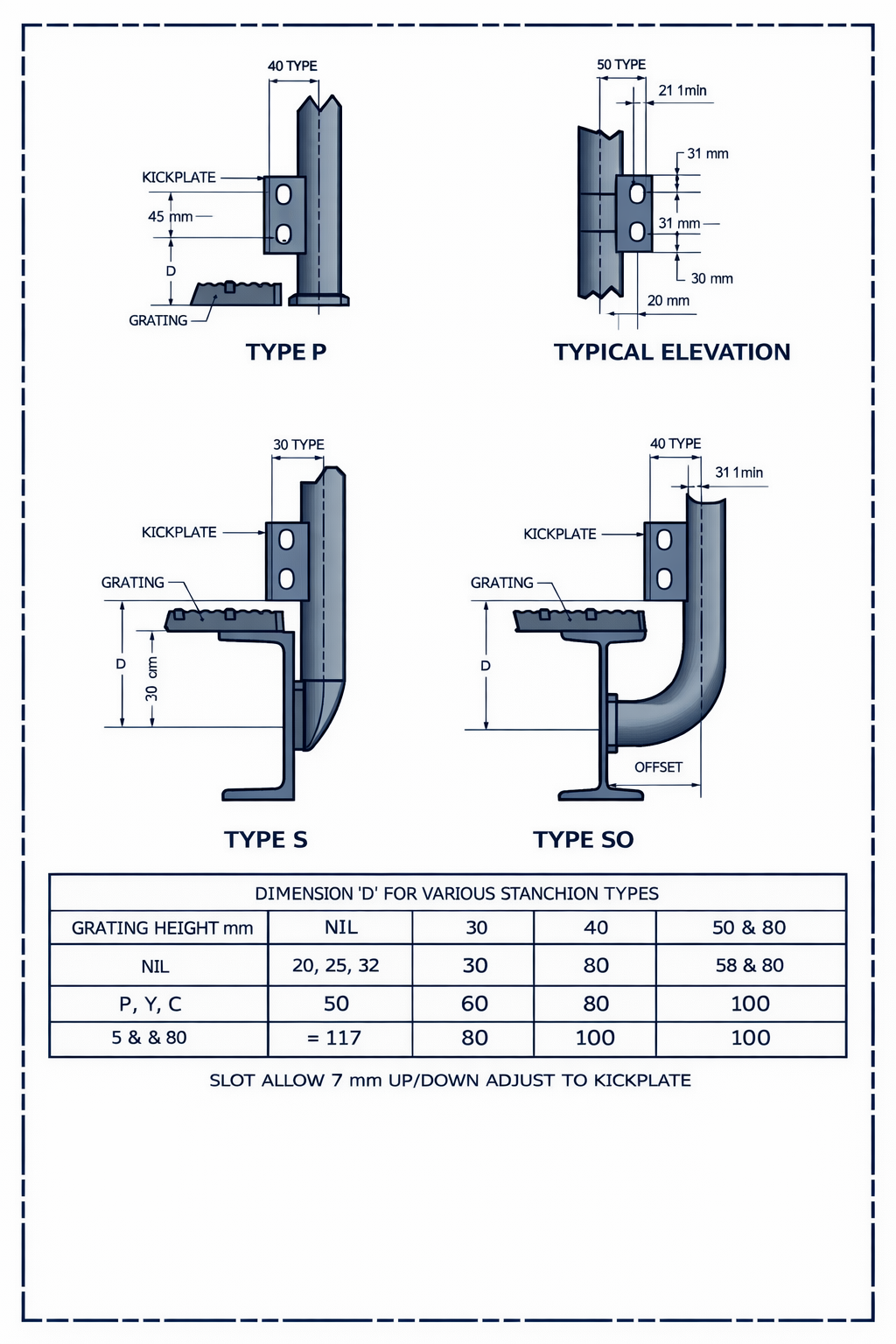

ASHMIC Handrail & Stanchion Systems

Safe, strong and simple barrier solutions for industrial applications

Tubular Ball Handrail System

ASHMIC Grating tubular ball handrail system is a safe, strong and simple barrier solution. The complete system lends itself to be quickly and economically erected in either a workshop or on site.

Manufactured in accordance with AS1657 and used extensively throughout the mining, petrochemical, mineral processing and heavy industries.

Available in component form (stanchions, bends, pipe and kick-plate) or can be supplied in fully fabricated panels for even quicker site installation.

AS1657 Compliant

ASHMIC Stanchion Product Range

Complete system components available in component form (stanchions, bends, pipe and kick-plate) or supplied in fully fabricated panels for quicker site installation.

Medium Duty (Standard)

- • 48.3 OD - 40mm NB

- • 3.2mm Gauge

- • 76mm OD Ball

Heavy Duty

- • 48.3mm OD - 40mm NB

- • 4.0mm Gauge

- • 76mm OD Ball

- • Stanchions drilled to suit rail

- • Custom drilling available on request

Aluminum

- • 50mm OD

- • 42mm NB

- • 76mm OD Ball

Rails Specifications

Standard Handrail

- • 32mm NB

- • 42.4mm OD

- • 3.2mm Gauge

Standard Kneerail

- • 25mm NB

- • 33.7mm OD

- • 3.2mm Gauge

Heavy Duty Kneerail

- • 32mm NB

- • 42.4mm OD

- • 4.0mm Gauge

Stanchions Product Weight

| Type | Product Code | Description | Med Duty MS Galv | Heavy Duty MS Galv | Alum | UOM |

|---|---|---|---|---|---|---|

| Stanchions | PA | Stanchion Type P | 4.8 kg | 5.25 kg | 2.05 kg | ea |

| PA | Stanchion Type PA | 4.8 kg | 5.25 kg | 2.05 kg | ea | |

| C | Stanchion Type C | 4.9 kg | 5.35 kg | 2.08 kg | ea | |

| CA | Stanchion Type CA | 4.7 kg | 5.35 kg | 2.08 kg | ea | |

| W | Stanchion Type S | 3.9 kg | 4.45 kg | 1.67 kg | ea | |

| WA | Stanchion Type WA | 3.9 kg | 4.45 kg | 1.67 kg | ea | |

| AMW | Stanchion Type AMW | 3.9 kg | 4.45 kg | 1.68 kg | ea | |

| S | Stanchion Type S | 5.05 kg | 5.65 kg | 2.2 kg | ea | |

| SC | Stanchion Type SC | 4.9 kg | 5.45 kg | 2.1 kg | ea | |

| SO | Stanchion Type SO | 5.4 kg | 5.9 kg | 2.5 kg | ea | |

| SA | Stanchion Type SA | 4.9 kg | 5.45 kg | 2.1 kg | ea | |

| SAR | Stanchion Type SAR | 4.9 kg | 5.45 kg | 2.1 kg | ea | |

| SOAL | Stanchion Type SOAL | 5.35 kg | 5.65 kg | 2.3 kg | ea | |

| AMW | Stanchion Type AMW | 4.5 kg | 5.05 kg | 1.68 kg | ea | |

| ORP | Stanchion Type ORP | 1.7 kg | 1.95 kg | 0.7 kg | ea | |

| ORS | Stanchion Type ORS | 2 kg | 2.35 kg | 0.88 kg | ea | |

| ORH | Stanchion Type ORH | 1.5 kg | 1.65 kg | 0.59 kg | ea |

Bends Product Weight

| Product Code | Description | Med Duty MS Galv | Heavy Duty MS Galv | Alum | UOM |

|---|---|---|---|---|---|

| RB32 | Rail Bend 32NB | 1.73 kg | 2.28 kg | — | ea |

| RB25 | Rail Bend 25NB | 1.34 kg | 1.76 kg | — | ea |

| RB46 | Rail Bend 46OD | — | — | 0.8 kg | ea |

| RB38 | Rail Bend 38OD | — | — | 0.6 kg | ea |

| CBA | Closure Bend Angled | 2.79 kg | 3.42 kg | — | ea |

| CBH | Closure Bend Horizontal | 2.82 kg | 3.76 kg | — | ea |

Pipe Product Weight

| Product Code | Description | Med Duty MS Galv | Heavy Duty MS Galv | Alum | UOM |

|---|---|---|---|---|---|

| P32 | Pipe 32NB | 3.1 kg | 3.8 kg | — | mt |

| P25 | Pipe 25NB | 2.41 kg | 2.94 kg | — | mt |

| P46 | Pipe 46 OD | — | — | 1.3 kg | mt |

| P38 | Pipe 38 OD | — | — | 0.97 kg | mt |

Kickplate Product Weight

| Product Code | Description | Med Duty MS Galv | Heavy Duty MS Galv | Alum | UOM |

|---|---|---|---|---|---|

| K1006 | Kickplate 100x6 | 5.32 kg | — | 1.6 kg | mt |

ASHMIC Bends & Components

Comprehensive range of bends, base plates, and mounting brackets

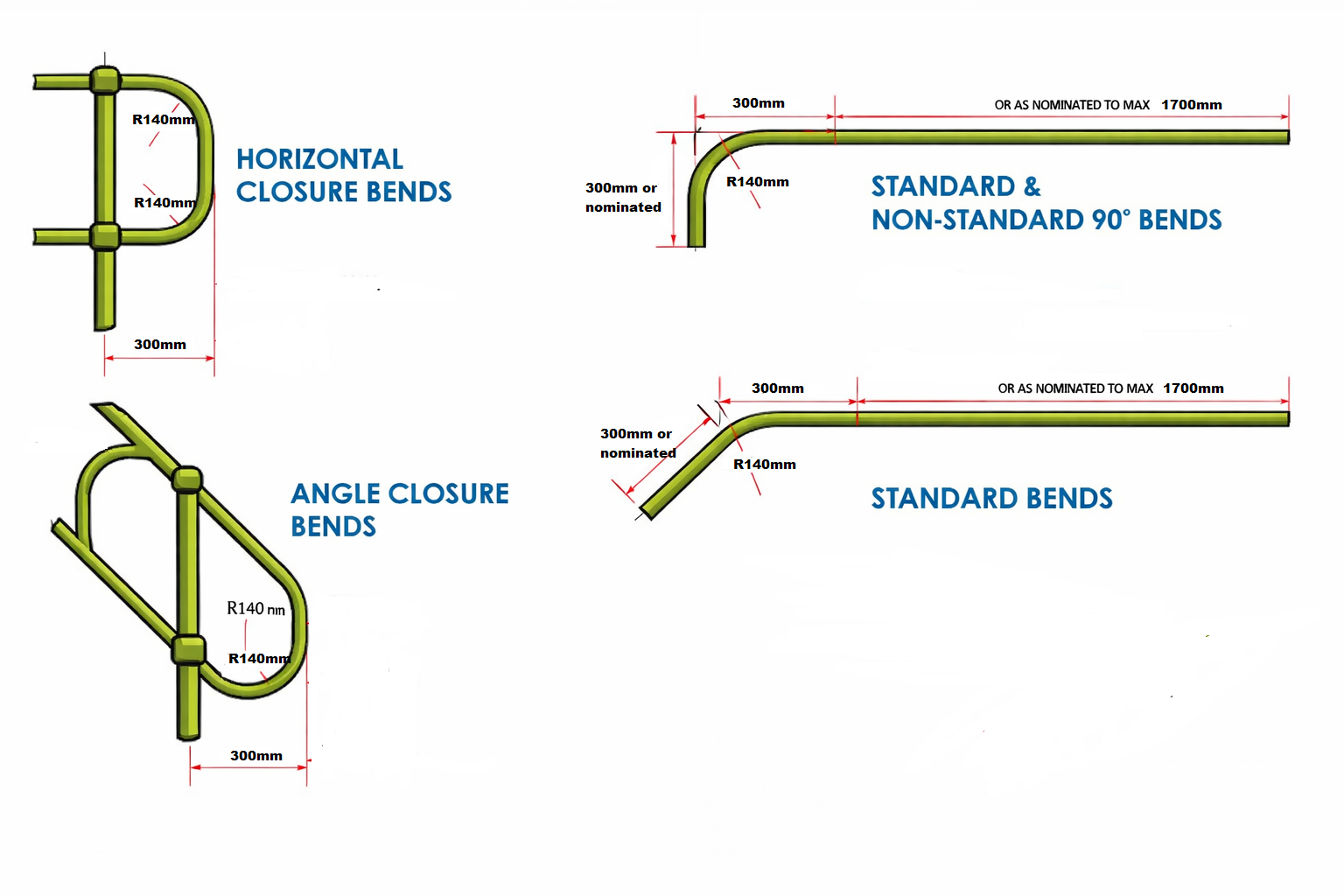

Horizontal Closure Bends

Horizontal closure bends have a wall thickness of 3.2mm. A standard 90° closure bend has a 140mm radius.

- • Bends have 300/600mm legs at 457mm centers

- • 3.2mm wall thickness

- • 140mm radius

Standard & Non-Standard 90° Bends

A standard 90° bend has a 140mm radius with 300mm legs. Non-standard bends available with 140mm radius.

- • 140mm radius

- • 300mm legs

- • Custom angles available

Angle Closure Bends

Angle closure bends have 140mm radius bends, with 300/300mm legs at 457mm centers.

- • Made to order to nominated angle

- • 140mm radius bends

- • 300/300mm legs at 457mm centers

Standard Bends

Special angles are made to suit customer's requirements. Always specify angles as shown, either A or B.

- • Custom angles available

- • Made to customer specifications

- • Angle specification: A or B format

Bends & Components

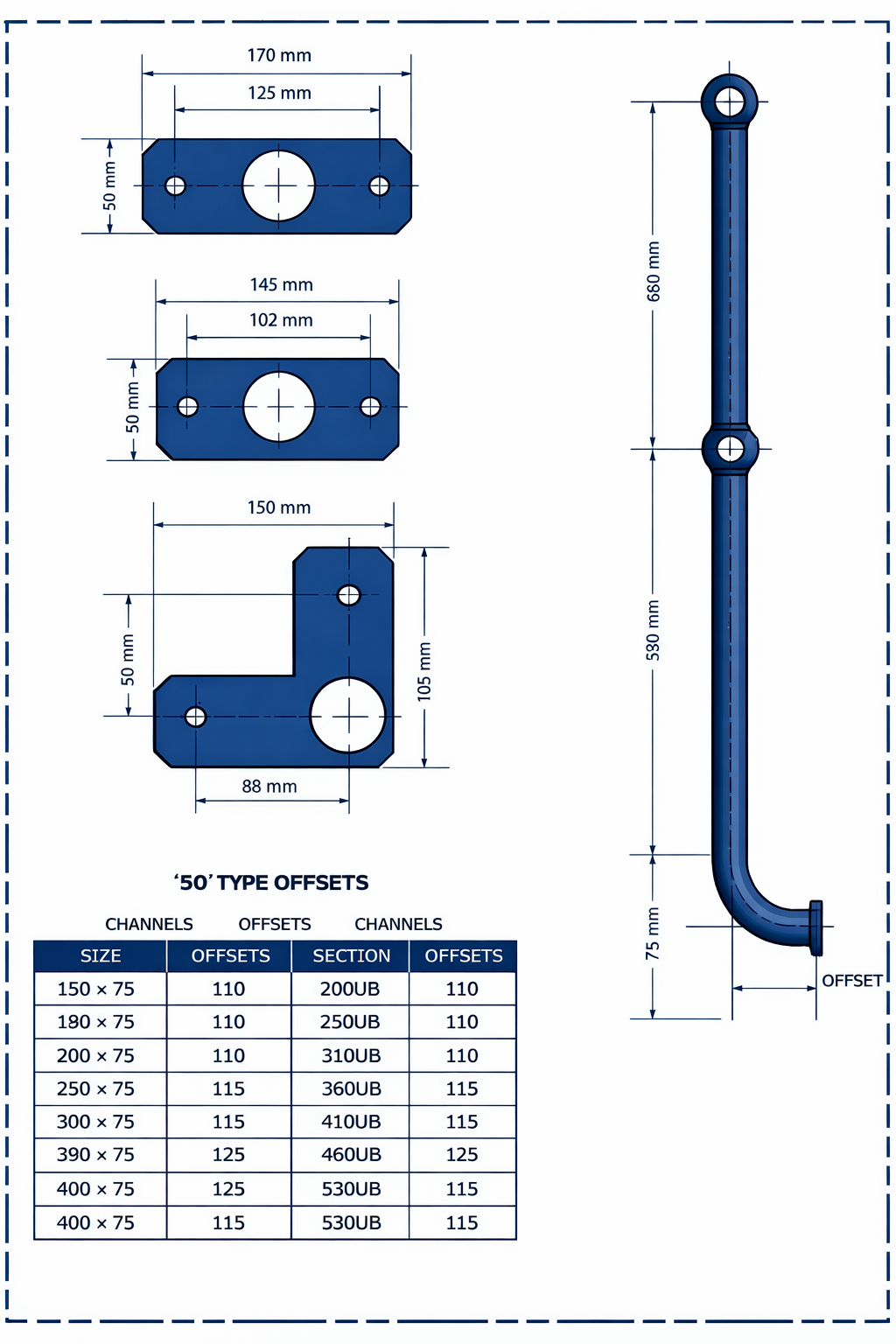

ASHMIC Steel Base Plates

Steel Base Plates

Robust steel base plates designed for secure stanchion mounting and long-term stability in industrial applications.

Kickplate Mounting Brackets

Mounting Brackets

Specialized mounting brackets for kickplate installation, ensuring proper alignment and secure attachment to handrail systems.

Ready to Enhance Your Industrial Infrastructure?

Contact our experts to discuss your steel grating and stanchion requirements. We provide customized solutions for projects worldwide.